Ford 8.8 Axle Swap Kit For Jeep Wrangler TJ

Tired of Broke C-Clips and Bent Axles?

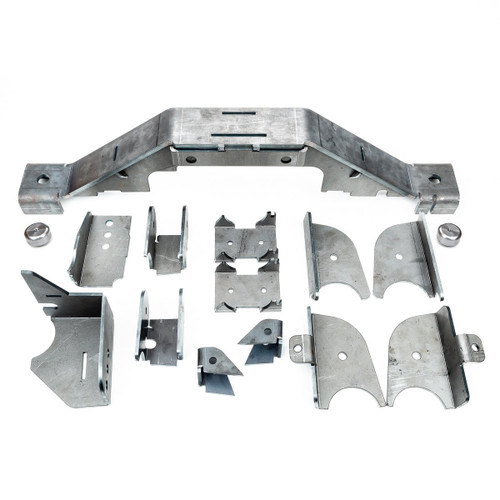

Time to swap out that tired, old Dana 35 axle under your Jeep TJ Wrangler? Look no further, our swap kit includes all of the brackets and tabs to turn your 8.8" Ford Explorer axle into a drop in swap.

This kit includes everything to replace your link mount points, coil buckets, anti sway-bar connections and trac-bar mount.

The most commonly swapped 8.8" axle is the Ford Explorer rear differential. This will give you the same jeep bolt pattern, larger axle tubes, disk brakes (1995 and newer), 31 spline shafts, and a trac-loc differential. Be sure to compare your gears against the 3.73:1 gear ratio that comes in the Ford axle from the factory and adjust accordingly.

Kit uses factory mounting widths and locations for all mounting points.

What's Included

- Sixteen (16) Piece Ford 8.8" Axle Swap Kit

- coil bucket requires 1/2 20 TPI bolt, length varies on what spring is used.

- Product Type:

- Link Kit